How to sharpen knives and odd shaped cutting edges, with a Block sharpener

The Block family are the Original Manufacturers of these style Knife Sharpeners est.1969.

(Aka; Butcher Block sharpener & later years Easy sharpener.) Don’t be fooled by look Alike’s, they do not work the same. Block sharpeners are a patent sharpener made to reline and hone blades back to their original cutting edges.

You will find our sharpeners can take knives much sharper than brand new.

Here are some knife sharpening videos to show you different techniques I use to sharpen different types of blades and cutting edges that you may find around your home. with Blocks patent flex design in the handle design this enables the honing rods to adjust to many different types of cutting edges.

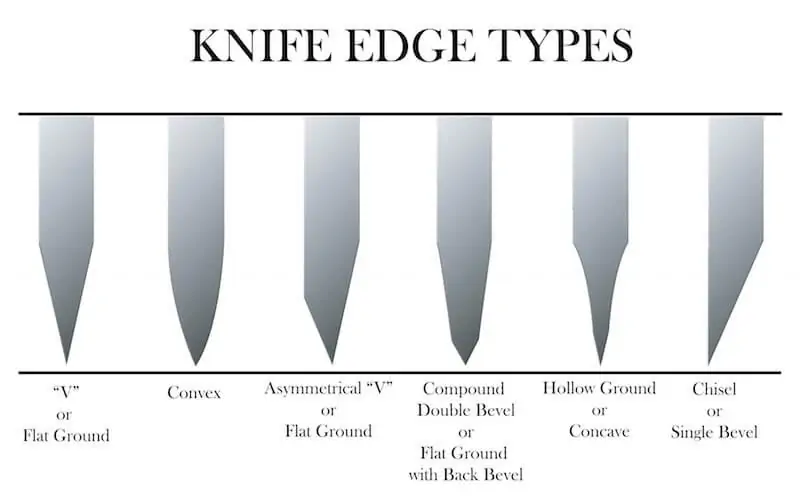

Knife Edge Styles

- V-edge the V-edge is the most common style for kitchen knives. …

- Double bevel or Compound Edge A double beveled edge, also known as a compound edge, is essentially a double-layered V-edge. …

- Chisel edge Chisel edges are most commonly found on Japanese sushi knives like Santokus and Nakiris. …

- Convex edge …

- Hollow edge …

- Serrated edge …

- Granton edge …

Cutting edges that you can sharpen with a Block sharpener.

Every knife blade is ground uniquely to form a sharpened edge. Each side of the blade that has honed an edge is referred to as a bevel. If you look closely at the blade of your kitchen knives, you should notice a part at the very edge that angles more steeply–this is the bevel.

Kitchen knives are easily one of the most commonly used tools on the planet. They are simple yet used for a variety of culinary tasks on a daily basis. But the very cutting edge that we rely on — and the source of the knife’s power–is nearly invisible to the unaided eye, a reason why we seem to take these trusty instruments for granted.

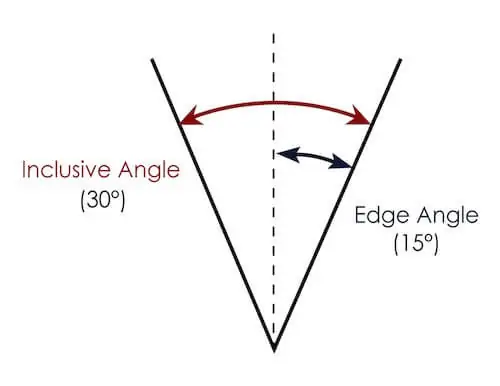

The majority of kitchen knives are flat ground, meaning the blade begins to taper from the spine to the edge. However, knife edges come in a variety of styles and differences in the way the blade is ground to make it sharp.If you look closely at the blade of your kitchen knives, you should notice a part at the very edge that angles more steeply–this is the primary bevel. Most of the time people refer to the Edge Angle—see the image below. Typically, this is about 15º to 25º for kitchen knives.

See how we do it videos.

You will find with our unique flex design in our sharpener handle you can sharpen many different types of cutting edges. Like all V -shaped edges form 16 Degrees threw 28 Degrees, Convent edges, Serrated edges, Scissor edges and odd shaped blades like found on Snake shaped Daggers or hawkbill work knife.

Popular steels and cutting edges found in knives that can be sharpened with a Block sharpener.

Damascus steel is produced by forging two different steel grades together and applying an acid-etching process to create beautiful, unique patterns. Although they are better known for their aesthetic appeal, Damascus steel knives can also be strong and durable, depending on materials used and forging skill.

Specific types of steel do not fall into the three traditional categories. The most well-known example is Damascus steel, which does not refer to a single alloy. Instead, the term refers to a mix of multiple layered steel alloys forged together.

Due to the complexity of the manufacturing process, Damascus knives are typically produced in small quantities only by specialized artisans and knife-making shops. They are recognizable by the unique wavy patterns on the blade formed during the forging process.

Although the durability and properties of Damascus steel almost entirely depend on the types of steel utilized in its construction, typical high-quality Damascus blades sharpen great with a Block sharpener and are tough, durable, and highly corrosion-resistant, making them suitable for cooking, camping, and bushcraft. Some cheaper or wider bevel edges will not sharp that great. (Change knife the bevel.)

Carbon steels – Not hard and sharp, but prone to rust and corrosion. Good for survival knives and machetes.

Carbon steels typically contain high amounts of carbon and relatively low amounts of chromium. Depending on the carbon content, carbon steel alloys are further sub-categorized into three groups: low-carbon steel (0.25% or less), medium-carbon steel (0.25% to 0.60%), and high-carbon steel (over 0.60%). Here are a few examples of common carbon steels: Any carbon steel sharpens very easy on the Block sharpener.

- 1095: 1095 is a commonly encountered type of steel and one of the most widespread carbon steel for knife blades. It is high-quality steel with a high carbon content (approx. 0.95% on average). 1095 is employed in constructing numerous U.S. military fighting knives and bayonets, such as the KA-BAR and the M7, due to its high hardness and superior edge retention.

- 1060: 1060 steel contains less carbon than 1095: approx. 0.6% on average, making it somewhere between medium- and high-carbon steel. Although the lower carbon content results in decreased hardness and edge retention, it improves toughness and ease of sharpening, making it suitable for kitchen knives. The same properties make it ideal for use in bladed tools other than knives, such as axes and swords.

- Aogami No.1: Aogami steels are proprietary carbon steels primarily manufactured in Japan by Hitachi. Aogami No.1 is a high-carbon steel with a carbon content averaging between 1.2% and 1.4%. Although it is challenging to sharpen, the high chromium and tungsten contents result in exceptional hardness (64-65 HRC), a sharp edge, and superior edge retention, yet less brittle than most steels of similar hardness. It is primarily employed in Japanese kitchen knives.

BEST STEEL FOR BOWIE KNIVES / MACHETES

Bowie knives and machetes are survival blades that will take a beating in everyday use. Because these blades will be used for tough jobs, you’ll want to use a steel that is hard enough to last, but not so hard that it becomes brittle.

Carbon steel is a popular choice for bowie knives and machetes. Whenever possible, go for a steel with 0.30%-0.60% carbon because they are sufficiently hard without becoming too brittle during processing. C1045 would be a good choice for these types of blades.

Stainless steels – resistant to rust and corrosion, but less tough and sharp than carbon steel. Good for everyday use and kitchen knives

Stainless steel knives are characterized by a high chromium content, granting them superior corrosion resistance. Here are a few examples of common stainless-steel materials: I find they all sharpen and are easy to maintain a great edge with a Block sharpener.

- 440C: 440C is one of the world’s most widespread stainless steel, and the type of steel used in Numerous knife manufacturers produce blades out of 440C, to the point it is the standard by which other steel alloys are judged. 440C blades contain 1.1% carbon, 17% chromium, and small amounts of molybdenum, manganese, silicon, sulfur, and phosphorus. Knives made using this material feature moderately high hardness (57-58 HRC), excellent corrosion resistance, good edge retention, and good wear resistance. Sharpening a 440C knife is relatively challenging but possible with the right tools.

- 3Cr13: 3Cr13 steel is a relatively inexpensive martensitic stainless-steel type known for its moderate hardness (55 HRC), high toughness, and ease of sharpening. Its chromium content is 14%, and other alloying elements include manganese, silicon, nickel, phosphorus, and sulfur. Although the edge retention of the blade isn’t the highest, it is an ideal steel material for beginners learning the basics of knife sharpening and maintenance.

- 8Cr13MoV: 8Cr13MoV is another martensitic stainless steel alloy equivalent to the proprietary AUS-8. It contains 14.5% chromium, 1% manganese, 1% silicon, and trace amounts of molybdenum, vanadium, nickel, phosphorus, and sulfur. Although it is considered low-cost stainless steel are known for their high hardness (up to 62 HRC), excellent corrosion resistance, and high wear resistance. Many prominent knife manufacturers, such as Kershaw or Spyderco, Sog. use this steel for tactical and self-defense knives. VG-10 is a cutlery grade stainless steel produced in Japan. The name stands for V Gold 10 (“gold” meaning quality), or sometimes V-Kin-10 (V金10号) (kin means “gold” in Japanese). It is a stainless steel with a high carbon content containing 1% Carbon, 15% Chromium, 1% Molybdenum, 0.2% Vanadium, and 1.5% Cobalt. sharpens great with a Block sharpener.

best steel for kitchen knives

Stainless steel tends to be the steel of choice for kitchen knives. Stainless steel is armed with built-in corrosion resistance, which is ideal for knives constantly exposed to acidic substances and water. 420 steel is commonly used for cutlery knives. 440 steel is also popular for higher grade cutlery knives.

Tool steels – very hard and durable, but difficult to sharpen and maintain. Good for cutting tools and high-performance knives.

Tool steel is a category of high-carbon steel alloys designed to manufacture tools. Tool steels are renowned for their exceptional hardness and durability and superior edge retention when used to manufacture knives. Here are a few examples of tool steels commonly utilized to make knives: These can be sharpened on a Block sharpener, but blade must be in good shape. to dull may be imposable. Keep up with these knives and Block sharpener will keep them sharp.

- D2: D2 is a versatile tool steel alloy. It is rich in carbon (1.5%) and vanadium (1.1%) and contains moderate amounts of chromium (12%), low amounts of molybdenum and manganese, and trace amounts of silicon and phosphorus. D2 has both the high carbon content of high-carbon steel and a chromium content equivalent to that of typical stainless steel. It offers high hardness (up to 62 HRC), toughness, durability, corrosion resistance, and edge retention. The only disadvantage of owning a D2 knife is similar to all tool steels: it is extremely challenging to sharpen.

- CPM-D2: CPM-D2 (also called Powdered D2) is the powder metallurgy variant of the standard D2 tool steel. It features slightly more carbon (1.55%) and slightly less chromium (11.5%) than standard D2. While hardness is similar, CPM-D 2 are a little tougher and have slightly better wear resistance and edge retention. Additionally, the manufacturing process results in a more consistent and durable blade, making it an excellent choice for knives intended for self-defense, survival, or tactical applications. This high-performance steel is reserved for high end knives.

- S7: S7 steel is a general-purpose shock-resistant tool steel. This steel alloy is commonly found in chisels, shearers, dies, drills, punches, and many other tools designed to withstand extreme impacts. It contains low amounts of carbon (approx. 0.5%) and chromium (3-3.5%), small amounts of manganese, silicon, vanadium, and copper, and trace amounts of sulfur and phosphorus. Knives made of S7 tool steel are exceptionally tough, highly durable, and capable of reaching moderately high hardness levels (up to 58 HRC before heat treatment). While S7 isn’t as corrosion resistant as other tool steel materials, its relative ease of sharpening makes up for it.

CPM S30V

CPM S30V is a premium steel produced by Crucible. CPM S30V is very corrosion resistant and it retains an edge really well. It was designed for high-end kitchen cutlery and pocket knives. CPM S30V has a great balance of toughness, hardness, and edge retention.

VG10 or VG-10 or VG 10, is a high-end Japanese stainless steel, it’s high in carbon and Vanadium, it’s one of the most popular steels in Japan, sharpens great, I find they get razor sharp quite easy,

V-edge

The V-edge is the most common style for kitchen knives. Like the letter V, these blades slant directly from the spine to the edge at a symmetric angle.

V-edges are the preferred design for most kitchen knife makers as they are easy to sharpen and hold their edge longer, though durability is sacrificed in favor of a fine edge.

Chisel edge

Chisel edges are most commonly found on Japanese sushi knives like Santokus and Nakiris.

These blades are only ground on one side to form a single primary bevel, while the other side is left straight and flat. For this reason, chisel edge knives can be found in both left-handed and right-handed varieties.

The edge is usually sharpened between 20º and 25º, which comprises the total angle of the edge (the flat side has an angle of 0). Such an acute angle makes chisel edges exceptionally thin and sharp compared to most American and European knives.

This design makes chisel edge knives the preferred style for cutting delicate raw fish in sushi restaurants.

Hollow edge

Hollow edge blades, also known as concave edges, curve inward–the opposite direction of convex edges.

These blades can get very sharp, but the limited steel supporting the edge makes them more susceptible to damage. Hollow edges are usually reserved for hunting and survival knives.

Some bargain-brand butcher knives may employ a hollow edge, but most quality kitchen sets will feature a stronger V-edge.

Double bevel or Compound Edge

A double beveled edge, also known as a compound edge, is essentially a double-layered V-edge. Picture a large V with a smaller V on top of it. This is my favorite overall. It’s sharp and durable.

The secondary bevel, also known as a relief angle, serves to make the metal behind the edge thinner. In principle, a thinner-edged blade has a greater cutting ability given its lack of friction—but it is also more likely to sustain damage.

The idea behind a double bevel is to make the edge stronger and more resistant to rolling and cracking with the support of the secondary bevel.

Convex edge

Convex edge blades feature two outward arcs that slope in and intersect at the edge. The resulting look of the edge resembles the slope of an airplane wing.

The curved design puts more steel behind the edge, making it stronger and sharper than V-edged blades.

Since the creation of a convex edge is a bit more sophisticated than others, they can be more difficult to sharpen effectively with home sharpeners. Because of this, convex edges often lose their shape and are eventually shaved down to V-edges.

Serrated edge

Like chisel edges, serrated-edged blades are ground on only one side. The distinguishing features of serrated edges are the mini-arches, or teeth, that serve to protect the actual cutting surface and keep the edge sharp. block sharpener will sharpen any serrated edge knife.

© 2024 , Stay sharp Block Knife Sharpener. All Rights Reserved. Designed By Digital Guider